SAKANN offers huge savings in embodied energy over traditional building materials while providing unmatched protection from the elements

RAPIDWALL is a load bearing building panel with a multitude of uses for the construction industry. It is ideal for just about any construction in which current building practices are used and is suitable for single, double, or multistory housing, as well as for commercial and industrial development. RAPIDWALL eliminates the need for bricks, timber wall frames, and plasterboard as it serves as both the internal and external load bearing wall.

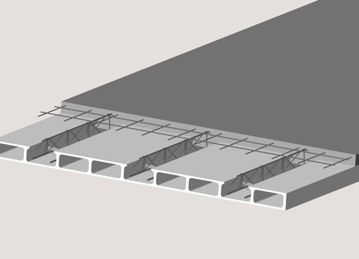

Because of its low energy and environmental credentials, RAPIDWALL is particularly suitable in areas where traditional building materials -- that have high energy usage, high carbon emissions or cause degradation to the environment -- are no longer sustainable. RAPIDWALL panels are manufactured in a molding process, from high-grade gypsum plaster and fiberglass rovings to a size of 12 m x 3 m x 123 mm. The hollow sections, or voids, have 250-mm centres.

The panels are cut in the factory to design specifications to a maximum tolerance of 5 mm. After cutting, the panels are loaded onto collapsible frames called stillages, ready for transport to the building site. Up to 500 m² of RAPIDWALL can be transported on one truck.The panels are lowered into position using a small crane and supported by props until the structure is completed. The formed cells can be filled with insulation for increased thermal performance or with concrete for increased load bearing structural capacity.

The three figures in the right-hand column refer to fire resistance periods for satisfying structural adequacy, integrity, and insulation, respectively. Fire resistance levels marked with an asterisk are test results from previous 100 mm RAPIDWALL panel tests. These results are deemed to be applicable to 123 mm thick RAPIDWALL .

| Description | Fire Resistance Level | |

|---|---|---|

| Non load Bearing Walls | Single leaf unfilled RAPIDWALL panel | 180/120/60* |

| Single leaf panel filled with Rockwool batts | 180/90/90* | |

| Load Bearing Walls | Single leaf panel filled with 12mm scoria aggregate | 30/30/30* |

| Single leaf panel filled with no scoria aggregate | 120/120/120* |

| Specifications | Unfilled | Filled with concrete |

|---|---|---|

| Weight (123mm RAPIDWALL) | 44 kg/m² | 250 kg/m² |

| Sound rating (Rw) | 28 | 49 |

| Fire Rating | 1 hour | 4 hours* |

| Ultimate Design Bending Capacity | Ø x 2.5 kNm per metre width | Ø x 22.7 kNm per metre width |

| Load Bearing Capacity | 100kNm – 2 Stories residential | 870kNm filled with 20 Mpa concrete – 8 stories (Typically) |

| Void volume / M2 | 86 L/m² | N.A. |

| Horizontal shear strength | 50kNm | T.B.A. |

| Axial Load capacity / compressive strength | 160kNm | T.B.A. |

| Water Absorption | Less than 5% after 24 hours immersion | T.B.A. |

Protection from all the elements – fire, hurricanes, cyclones, and temperature.

- Produced from inert gypsum plaster, RAPIDWALL has a 1-hour fire rating when unfilled or a 4-hour fire rating when filled with concrete

- By using a simple tiedown system, the roof is secured through the cavity of the wall to the foundation, giving it significant protection against high winds

- Further, RAPIDWALL has a high thermal insulation, and when the hollows are filled with insulation, even greater thermal properties are achieved

Saves energy and the environment

In his thesis, Ecologically Sustainable Development – Approaches in the Construction Industry, Robert Omahen, University of Regensburg concludes that:

“RAPIDWALL offers huge savings in embodied energy – 66% for domestic buildings 40% for commercial buildings.” He further states that RAPIDWALL uses “fewer raw materials but doesn’t compromise on load bearing capability and the total CO2 saving of RAPIDWALL for residential dwellings in Australia would be about 63% or 3.91 million tonnes compared to brick.”

- The manner in which RAPIDWALL is manufactured means that both sides, the internal and external surfaces, are finished to a very high quality -- thereby dramatically reducing construction and finishing time

- Furthermore, the clean, dry construction process eliminates the need for bricklaying and most plastering

More cost effective than other building products

The following chart is based on the construction of a 130 m2 demonstration house in Mumbai, India:

Low energy cost for production

- Produced from cost effective and abundant materials

- RAPIDWALL is cyclone resistant. Using a simple tiedown system, the roof is secured through the cavity of the wall to the foundation